Do you know how to maintenance your breaker?

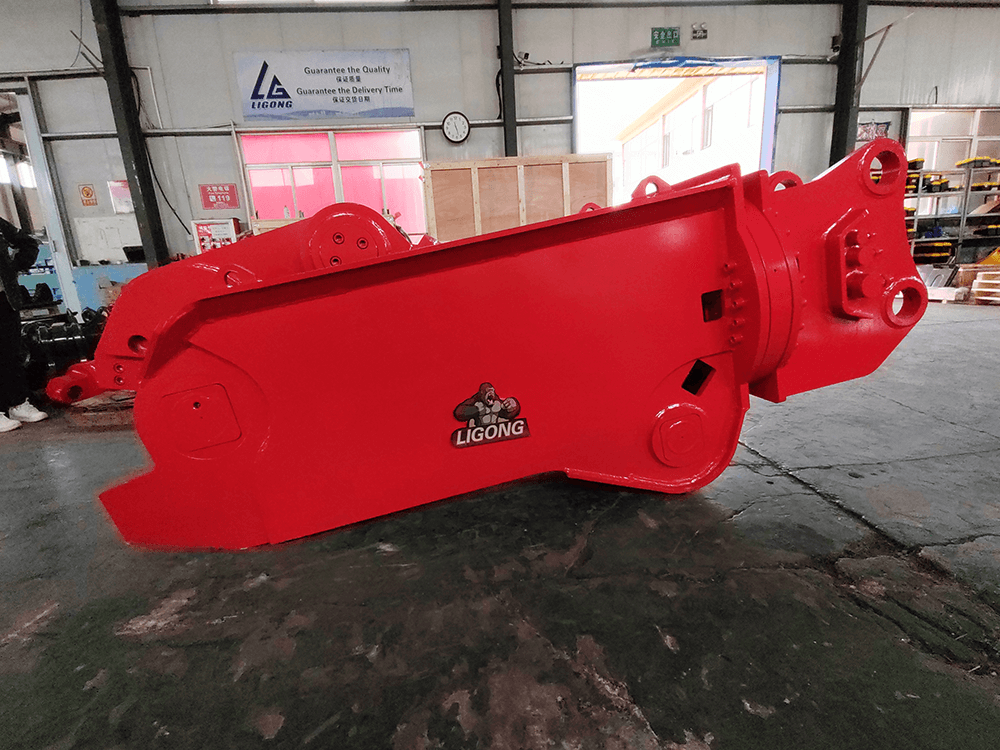

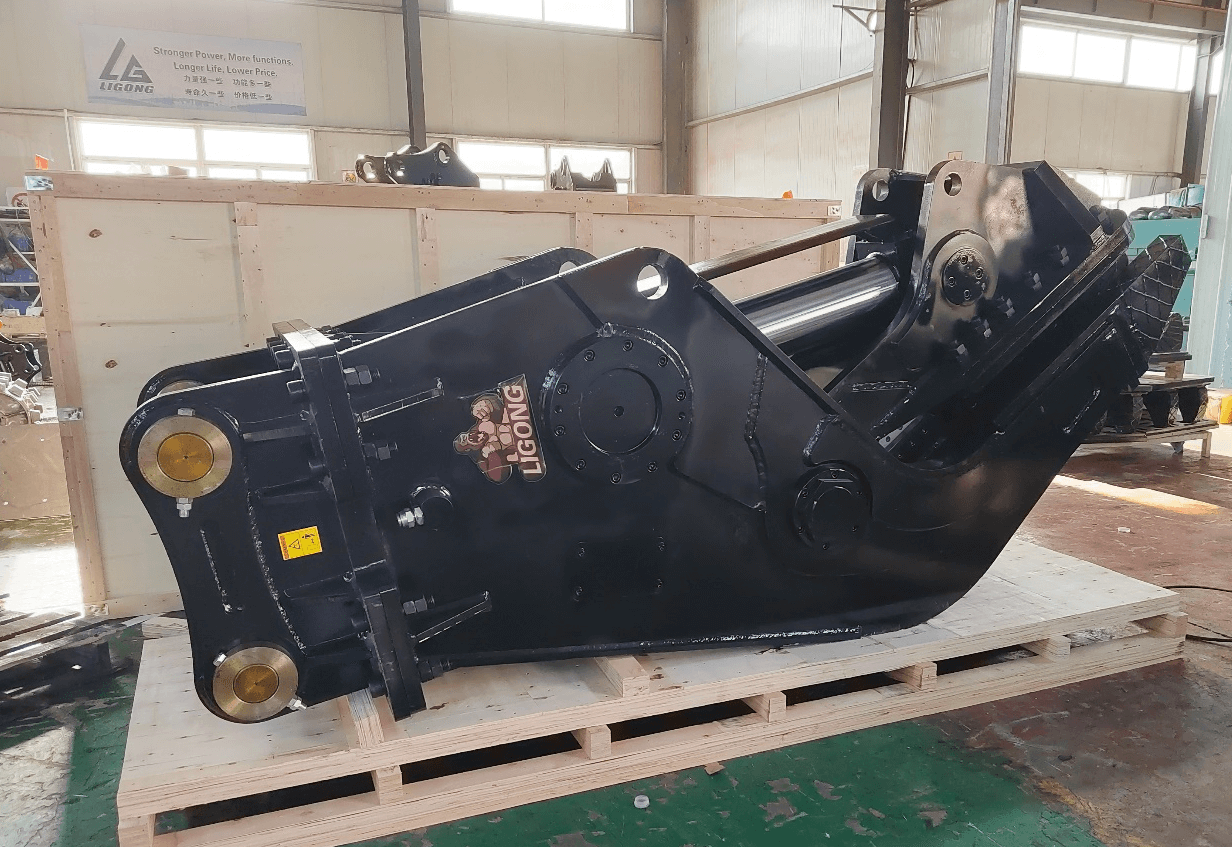

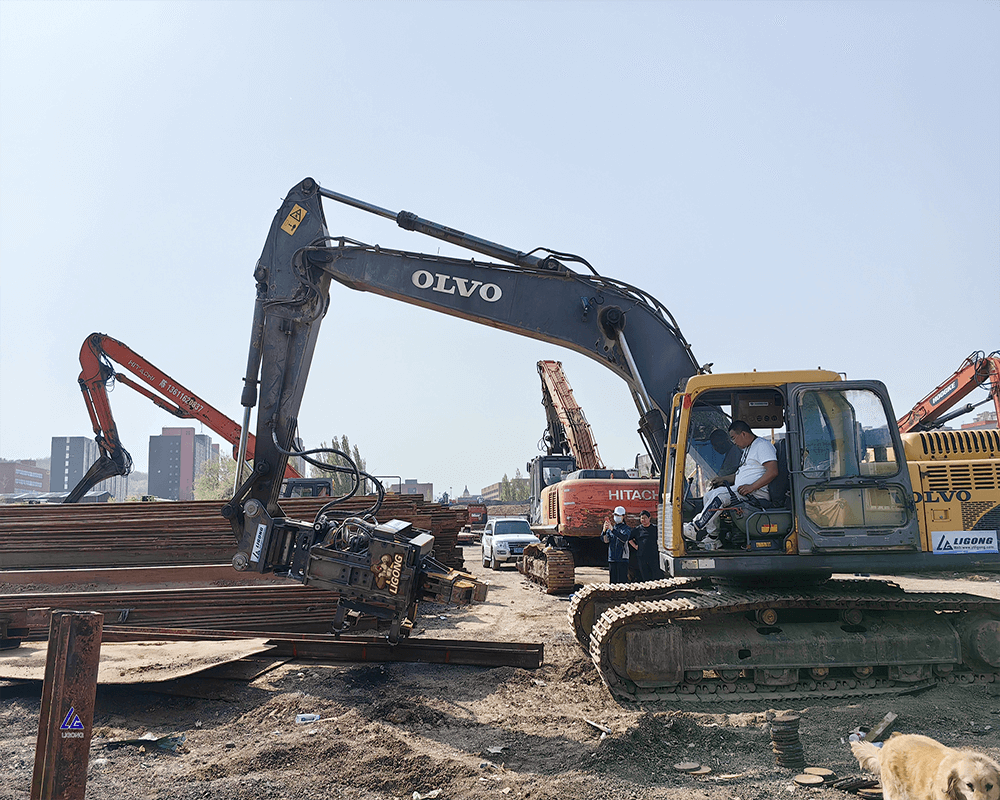

LG Hydraulic breakers design for breaking rock, concrete, asphalt, and other construction materials.

To ensure its longevity and optimal performance, routine maintenance is crucial.

Here are some key maintenance tips to follow:

Routine Walk-Around Inspection

Performing a visual inspection before each use is vital.

It helps identify worn or damaged components early, preventing unexpected downtime.

Daily checks should include:

- Hydraulic hoses

- Breaker shell

- Attachment pins

- Tool retainers and locks

- Tool points for cracks or gouges

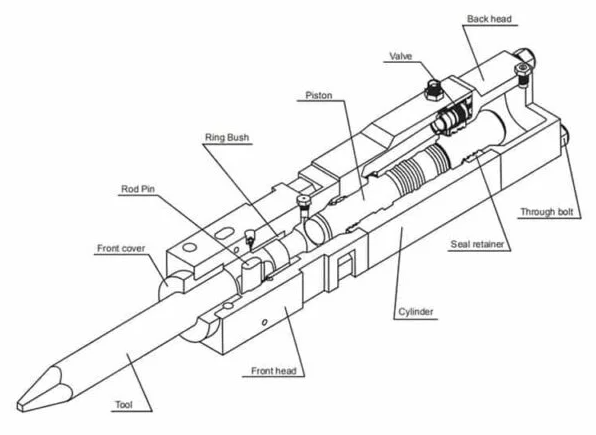

Inspect Breaker Bit, Pin, and Bushing

Regularly check for loose or broken bolts and worn bushings. If the tool appears loose in the bushings, measure and record the play.

Misalignment can damage the piston and cylinder.

Inspect tool retaining pins every week or 50 hours of operation for damage and ensure sufficient grease is applied.

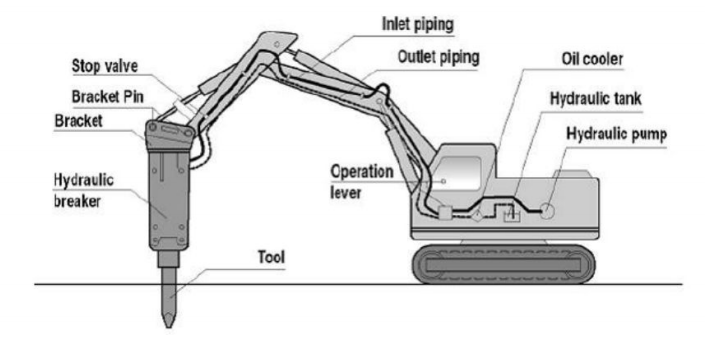

Inspect Hydraulic Hoses

Ensure hydraulic hoses are the correct length and properly routed to minimize wear and downtime.

Hoses that are too short restrict extension, while longer hoses can catch on debris.

Properly sized and routed hoses maximize operating time and protection.

Applying Grease

Greasing is the most critical maintenance task.

It lubricates and clears debris from the tool bushing area.

Proper greasing prevents metal-to-metal contact, reducing wear on major components.

Apply grease until it comes out of the lower bushing area.

Use a No. 2 lithium-based grease with three percent moly rated to 500 degrees Fahrenheit.

Inspect Nitrogen Pressure

Many hydraulic breakers feature a nitrogen gas assist that should be maintained.

Monitor the breaker’s performance for signs of low gas pressure.

Check gas charges weekly, adjusting for application and ambient temperature as specified in the Operation and Maintenance Manual.

Size It Right

Hydraulic breaker attachments must be properly sized to the specific carrier.

Incorrect sizing can diminish the breaker's impact or damage components.

Ensure the breaker matches the carrier’s performance for effective material breaking.

By following these maintenance tips, you can extend the life of your hydraulic breaker and improve its performance across various job sites.